Understanding Shortage Allowances

read more

The International Maritime Solid Bulk Cargoes Code (IMSBC Code) introduced a new schedule for ‘Group A’ bauxite fines, which may liquefy, and reviewed the previous schedule for ‘Group C’ bauxite, which does not. The adoption of these regulations became mandatory from 1 January 2021.

Previously, bauxite cargoes used to be classified simply as Group C cargo under the IMSBC Code, that is, neither prone to liquefaction nor to possess a chemical hazard. However, there are certain grades of the aluminium ore containing a higher proportion of fines, and sufficiently high moisture content which may, under certain conditions, cause the bauxite to liquefy.

In the wake of the tragic loss of the bulk carrier BULK JUPITER, which sunk off the coast of Vietnam in 2015 with only one of her nineteen crewmembers surviving while carrying Malaysian bauxite to China, the International Maritime Organization (IMO) researched the matter extensively with global stakeholders and authorities. It acknowledged that the disaster might have been caused by cargo liquefaction – or, more accurately, “cargo dynamic separation” – and that some grades of bauxite cargoes should be treated following the Code provisions for Group A cargoes.

A new test procedure for determining the transportable moisture limit (TML) for seaborne bauxite was developed and submitted to the IMO member states for approval along with drafts for a new individual schedule for Group A bauxite (referred to as bauxite fines). Amendments to the Group C bauxite schedule were also made and eventually approved, and these are now in force.

The distinction between the two schedules lies primarily with the cargo particle size:

Group C bauxite:

a) cargo containing either:

Or:

b) where the shipper provides the master with a certificate, in accordance with the result of the test (Modified Proctor/Fagerberg) approved by the competent authority of the port of loading

Group C bauxite fines:

Cargo containing both:

Bauxite cargoes meeting the above criterion may be carried as a Group C cargo per the provisions of the individual schedule for bauxite where the shipper provides the master with a certificate, in accordance with the result of the test approved by the competent authority stating that the moisture of the cargo freely drains from the cargo so that the degree of saturation is not liable to reach 70%.

Bauxite in Brazil

Bauxite is only behind iron ore as the most abundant metallic mineral available in Brazil, which holds the fourth-largest deposits after Guinea, Australia and Vietnam. Brazil is the fourth global bauxite producer, behind Australia, Guinea and China. Brazilian bauxite reserves are of the prime quality with over 40% of aluminium dioxide content.

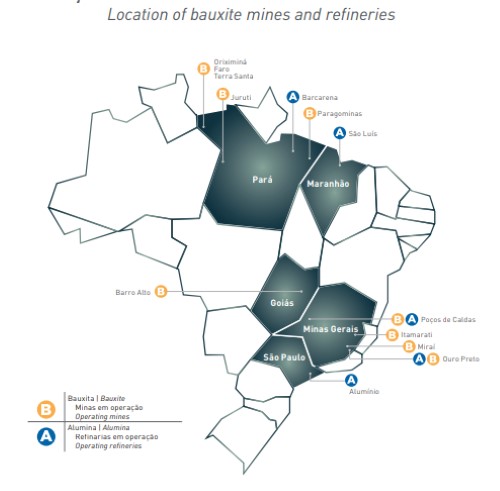

More than 90% of the Brazilian bauxite mines in operation are located in the northern state of Para in the Amazon Region. Regular shipments depart from the river ports of Trombetas and Juruti to supply the domestic aluminium-making industry in the port complex of Vila do Conde (Barcarena) in Para, and in the port of São Luis, state of Maranhao, which retains about three-fourths of the production. About two-thirds of all bauxite shipments depart from Trombetas and one-third from Juruti.

Three multinational conglomerates dominate the national bauxite production. Minerações Rio do Norte (MRN), a joint venture including Vale, Rio Tinto, Alcoa and Norsk Hydro, is a major bauxite miner and export leader, extracting the aluminium ore from the Oriximina mines in western Para and shipping it in barges and bulkers shuttling between its port terminal in Trombetas and Vila do Conde.

Norwegian mining giant Norsk Hydro flows its bauxite production from the Paragominas mines in northeast Pará through a 244-Km pipeline down to its alumina refinery (Alunorte) and aluminium-making factory (Albras) Barcarena, which also receives bauxite shipments from Trombetas through Vila do Conde.

American aluminium-maker Alcoa ships bauxite from its port terminal in Juruti, northwest Para, to its share held alumina refinery in São Luis (Alumar). Alcoa also operates a port terminal in Itaqui shipping in bauxite, caustic soda and fuels and shipping out alumina produced locally.

In 2019, around 31,730 million metric tons (mmt) of bauxite were handled in Brazilian ports, 6,925 mmt of which were shipped abroad. Until October 2020, 28,732 mmt of the mineral had already been handled in the domestic ports, of which 4,224 mmt were exported.

Local risks

The Amazon region is Brazil’s rainiest region with precipitation and humidity levels growing in intensity and frequency between December and May, a period which locals termed Amazon Winter (due to the softening of thermal sensation compared to the dry season). The IMSBC Code provides that the moisture content (MC) of the bauxite fines must be kept lower than its TML during loading operation and throughout the voyage. It also warns that cargo must not be loaded during rain, unless otherwise provided by the Code. It also warns that all non-working hatches which the bauxite is to be loaded should be kept closed.

Despite the climatological risks inherent to the Northern Arc ports, there are no reports of recent shipping casualties attributable to dynamic separation and shifting of bauxite cargoes loaded at Brazilian Ports and the port operators keep stringent quality control systems in place.

Nevertheless, shipowners and masters must always be vigilant and ensure that the correct cargo declaration and up-to-date certificates are provided by the shippers and that the cargo condition meets what has been declared, failing which the master must deny carriage.

In case of doubt, the vessel’s P&I club should be notified to prompt its local correspondents to assist.

Please read our disclaimer.

Rua Barão de Cotegipe, 443 - Sala 610 - 96200-290 - Rio Grande/RS - Brazil

Telephone +55 53 3233 1500

proinde.riogrande@proinde.com.br

Rua Itororó, 3 - 3rd floor

11010-071 - Santos, SP - Brazil

Telephone +55 13 4009 9550

proinde@proinde.com.br

Av. Rio Branco, 45 - sala 2402

20090-003 - Rio de Janeiro, RJ - Brazil

Telephone +55 21 2253 6145

proinde.rio@proinde.com.br

Rua Professor Elpidio Pimentel, 320 sala 401 - 29065-060 – Vitoria, ES – Brazil

Telephone: +55 27 3337 1178

proinde.vitoria@proinde.com.br

Rua Miguel Calmon, 19 - sala 702 - 40015-010 – Salvador, BA – Brazil

Telephone: +55 71 3242 3384

proinde.salvador@proinde.com.br

Av. Visconde de Jequitinhonha, 209 - sala 402 - 51021-190 - Recife, PE - Brazil

Telephone +55 81 3328 6414

proinde.recife@proinde.com.br

Rua Osvaldo Cruz, 01, Sala 1408

60125-150 – Fortaleza-CE – Brazil

Telephone +55 85 3099 4068

proinde.fortaleza@proinde.com.br

Tv. Joaquim Furtado, Quadra 314, Lote 01, Sala 206 - 68447-000 – Barcarena, PA – Brazil

Telephone +55 91 99393 4252

proinde.belem@proinde.com.br

Av. Dr. Theomario Pinto da Costa, 811 - sala 204 - 69050-055 - Manaus, AM - Brazil

Telephone +55 92 3307-0653

proinde.manaus@proinde.com.br

Rua dos Azulões, Sala 111 - Edifício Office Tower - 65075-060 - São Luis, MA - Brazil

Telephone +55 98 99101-2939

proinde.belem@proinde.com.br